We think that bringing together soft and rigid materials will help to create a new generation of fast, alert robots that are more healthy and flexible than their predecessors and can safely work side by side with humans,” said Michael Tolley, an assistant professor of mechanical engineering at University of California – San Diego. Tolley said that the thought of blending soft and hard materials into the robot’s body came from nature. For example, certain species of mussels have a foot that starts out soft and then becomes rigid at the point where it makes contact with rocks. Scientists said such leaping robots could one day come in use in harsh environments too hazardous for humans, particularly because the bots are capable of surviving hard falls and other unexpected conditions. Soft robots tend to be slow, especially when accomplishing tasks without being tethered to power sources and other electronics. Researchers hope that their work will allow rigid components to be better integrated within soft robots, which will then move faster without compromising the safety of the humans who would work with them. Stiff layers make for a better interface with the device’s electronic brains and power sources. The soft layers make it less helpless to damage when it lands after jumping.

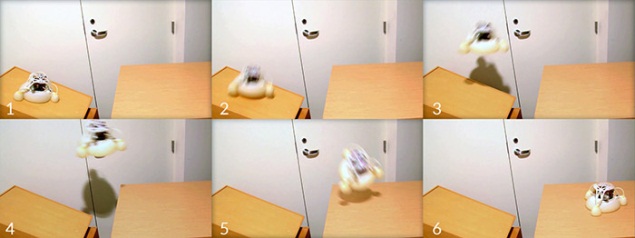

One wild possible application would be in space — on the moon or Mars or other planets,” said study co-lead author Nicholas Bartlett, a roboticist at Harvard University. You could also think of more practical use, such as search-and-rescue missions in disaster scenarios such as collapsed buildings, where a soft robot could go where no wheeled robot could navigate.” The combustion-powered bot has two main parts: a soft plunger-like body with three pneumatic legs and a rigid core component which containing power and control mechanism. The core module is protected by a semisoft guard created with a 3D printer. To commence movement, the robot inflates its pneumatic legs to tilt its body in the direction it wants to go. Harvard believes it is a powerful hopper, reaching up to six times its body height in vertical leaps and half its body size in cross jumps. In the field, the hopping motion could be an effective way to move quickly and easily around obstacles. “The wonderful thing about soft robots is that they lend themselves nicely to cruelty,” said Nicholas Bartlett, first author of the paper. The robot is made of two nestled hemispheres. The top hemisphere is like a half shell, 3D-printed in once piece, with nine different layers of severity, creating a structure that goes from rubber-like flexibility on the exterior to full rigidity near to core. Researchers tried several versions of the design and concluded that a fully firm top would make for higher jumps. But a more flexible peak was more likely to endure impacts on landing, allowing the robot to be reused. They decided to go with the more flexible design. The bottom half of the robot is flexible and includes a small chamber where oxygen and butane are injected before it jumps. After the gases are ignited, this half behaves very much like a basketball that gets inflated almost directly, propelling the robot into a jump. When the chemical charge is exhausted, the bottom hemisphere goes back to its original shape. The two hemispheres surround a rigid core module that houses a custom circuit board, high-voltage power source, battery, miniature air compressor, butane fuel cell and other components. The research was published in the journal Science magazine. The increasing width of materials attuned with 3-D printers is allowing engineers to prototype new designs faster and putting to bed the old saying that increased complexity necessarily leads to increased cost. “Soft robotics is a relativity promising subfield, and 3-D printing is adding to the range of things we can do in a really practical way,” said Wood. The research was published in the journal Science magazine.